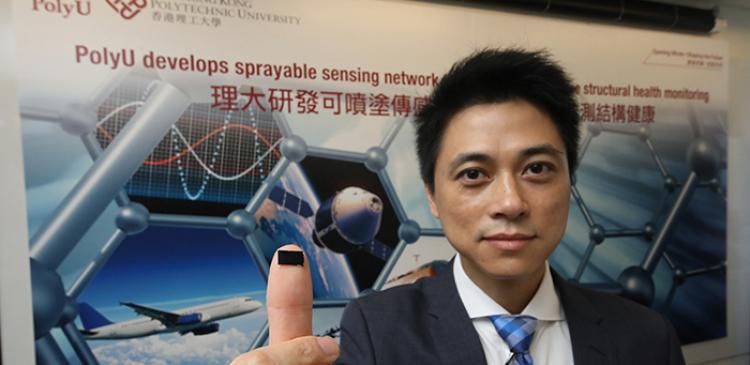

Light, flexible naonsensors sprayed onto engineered structures, including airplanes, can detect tiny cracks or other damage in real time.

Novel, nano-engineered sensors can now be sprayed directly onto flat or curved engineered surfaces, such as train tracks and airplanes. They can also be networked to render rich, real-time information on the health status of structures and detect hidden flaws. Conventional ultrasound sensors used to monitor structures in their normal environments are usually stiff, so they can’t adapt to curved surfaces. They are also usually bulky and heavy, limiting widespread deployment on the target structure. Researchers at The Hong Kong Polytechnic University (PolyU) have now developed nanocomposite sensors that are light, flexible and inexpensive, so large quantities can be sprayed onto a structure. They can even be applied to moving trains and airplanes. Made of a hybrid of carbon black, two-dimensional graphene, conductive nanoparticles, and polyvinylidene fluoride, the nanocomposite sensor can be easily tailored to different sizes to accommodate various needs. Compared to a conventional ultrasound sensor that costs over US$10 and weighs a few grams, PolyU’s nanocomposite sensors cost only US$0.5 each and weigh 0.04g. "This nanocomposite sensor is blazing a trail for in-situ structural health monitoring by striking a balance between the sensor cost and the amount of data acquired," says Su Zhongqing, who spearheaded the project with Zhou Limin. A number of sprayed nanocomposite sensors are combined with an ultrasound actuator, which emits guided ultrasonic waves, to create a flexible sensor network. If damage, such as a crack, is present in a structure being monitored, it will interfere with and scatter the ultrasonic waves. The sensors detect the wave scattering and translate those signals into 3D images, quickly and precisely characterizing the damage. The sensor can detect cracks as small as one or two millimetres in most engineering materials. That response frequency is over 400 times more than the highest frequency of other nanocomposite sensors, as reported in international journals. The secret to the sensor’s high sensitivity lies in its optimized nanostructure, which enables it to detect small changes in electrical resistivity under mechanical strain. Su and his team tested the weight ratio of nanofillers in order to optimize the sensor’s conductivity, and thus its sensitivity to electrical resistivity changes. The team’s research has been published in top-tier journals in this field, including Ultrasonics, Carbon, and Smart Materials and Structures. --------------------------------------------------------------------------------------- Asia Research News is our annual magazine to highlight exciting research studies from our partners. 25,000 copies are printed and distributed to key figures in research. Download a PDF copy from the link below or contact us if you would like print copies.