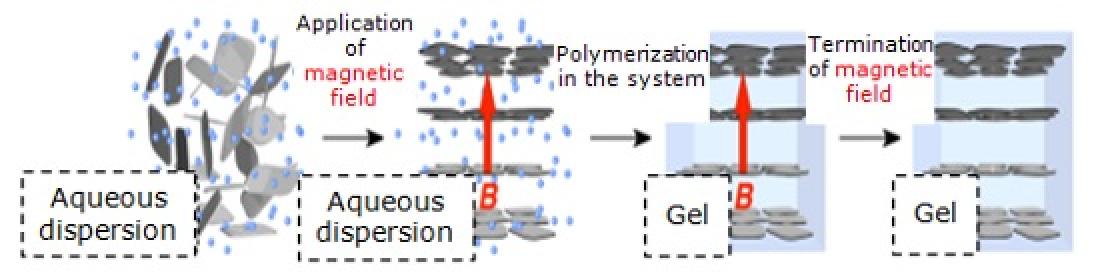

Figure 3 in the press release. Under a magnetic field, radical polymerization of vinyl monomers can proceed to produce hydrogel material whose structure is supported from inside by an electrostatic repulsive force. This process then causes the conversion of aqueous dispersion containing nanosheets into hydrogel. The structure of hydrogel, in which nanosheets are arranged in a parallel orientation, will be fixed semipermanently.

The joint research group led by Takuzo Aida and Yasuhiro Ishida at RIKEN and Takayoshi Sasaki at NIMS successfully developed a material that expresses a unique mechanical property by arranging oxide nanosheets, that electrostatically repel each other, in the direction perpendicular to a magnetic field, and by confining a three-dimensional nano-network structure in a water-swollen gel material, hydrogel. This study had been published in the UK scientific journal, Nature, doi:10.1038/nature14060. ( Mingjie Liu, Yasuhiro Ishida, Yasuo Ebina, Takayoshi Sasaki, Takaaki Hikima, Masaki Takata & Takuzo Aida, Article title: “An anisotropic hydrogel with electrostatic repulsion between cofacially aligned nanosheets”. Nature 517, 68–72 (01 January 2015) doi:10.1038/nature14060)

The joint research group led by Takuzo Aida, director, Emergent Soft Matter Function Research Group, Center for Emergent Matter Science, RIKEN (also a professor at the School of Engineering, University of Tokyo), Yasuhiro Ishida, leader, Emergent Bioinspired Soft Matter Research Team, RIKEN, and Takayoshi Sasaki, fellow, International Center for Materials Nanoarchitectonics, NIMS, successfully developed a material that expresses a unique mechanical property by arranging oxide nanosheets, that electrostatically repel each other, in the direction perpendicular to a magnetic field, and by confining a three-dimensional nano-network structure in a water-swollen gel material, hydrogel.

Devices that take advantage of electrical and magnetic repulsive forces include linear motors and magnetic bearings. These devices are capable of performing special functions due to the use of repulsive force in addition to attractive force. In contrast, structural materials such as ceramics and plastics had been strengthened by increasing the attractive force between their components as exemplified by the hybrids between organic polymers and inorganic particles. No attempt had been made to utilize repulsive force in designing structural materials. On the other hand, articular cartilage in animals is made of negatively-charged high-density polymers, and its high load bearing capacity and high wear resistance are attributed to the electrostatic repulsive force.

The joint research group between RIKEN and NIMS discovered that when a magnetic field was applied to the polyanionic titanium oxide nanosheets that are dispersed in water, all of the sheets turned to a position perpendicular to the magnetic field, and a huge, anisotropic electrostatic repulsive force was generated between the nanosheets arranged in a face-to-face orientation. The process of gelling the aqueous dispersion produces hydrogel material whose structure is supported from inside by an electrostatic repulsive force. Unlike ordinary materials, this material demonstrates a unique mechanical property of withstanding large loads applied vertically to it while easily distorting in the horizontal direction. As such, it performs outstandingly as a vibration-damping material.

This discovery illustrated that repulsive force, to which virtually nobody had paid attention, is extremely useful in controlling mechanical properties of structural materials, and may cast great influence on the designing of structural materials in the future. This study will be published in the UK scientific journal, Nature (January 1 issue).

This study was conducted as a part of the Impulsing Paradigm Change through Disruptive Technologies Program (ImPACT) sponsored by the Council for Science, Technology and Innovation, and was commissioned through the Japan Science and Technology Agency.