A model developed by KAUST researchers provides insights into how drilling muds behave within wells and could help the oil industry avoid clogged wells.

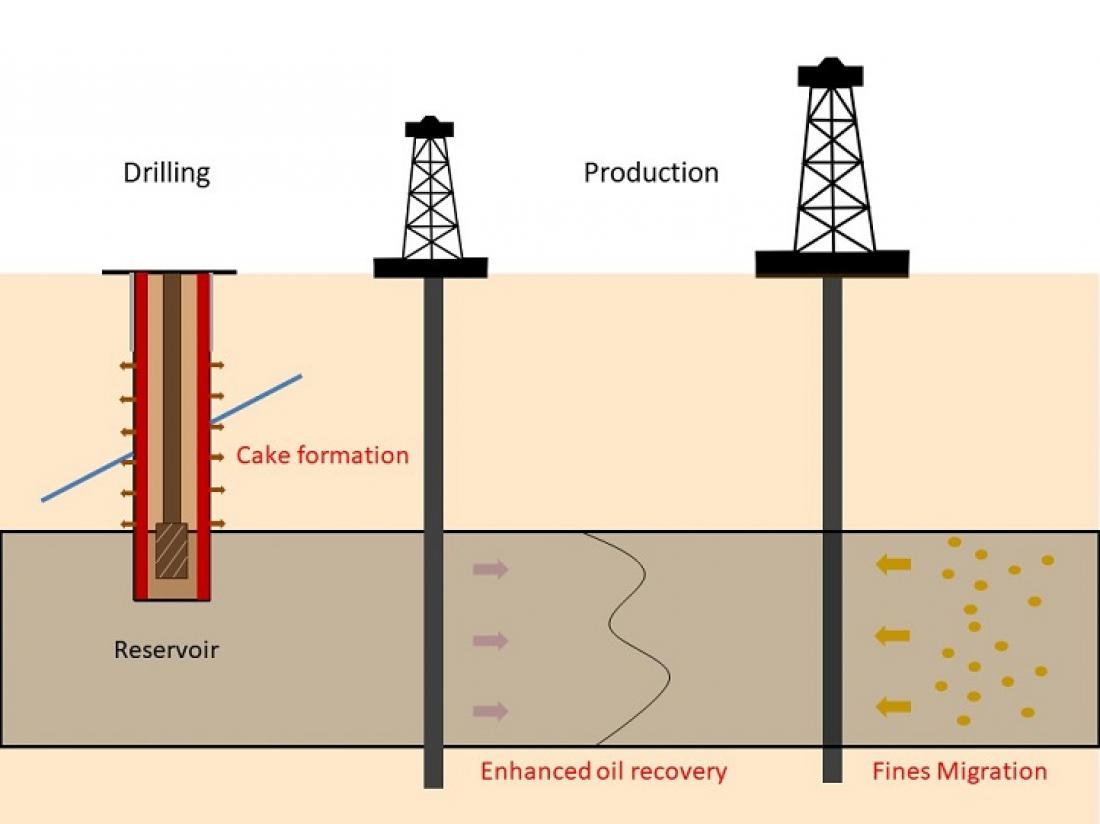

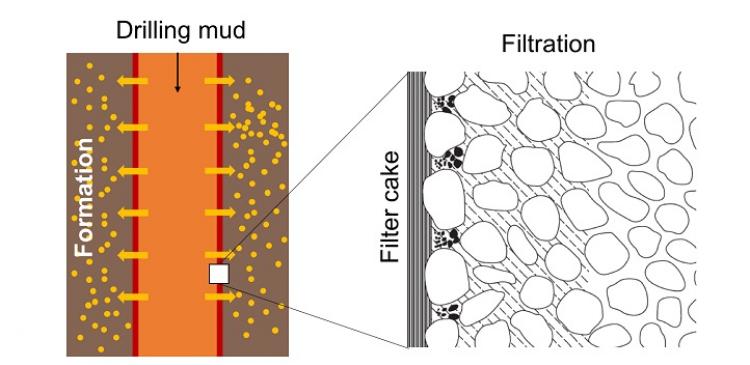

A model that simulates how drilling fluids, or muds, behave and influence the stability of oil wells has been developed by KAUST researchers. Their findings could inform new safety protocols and the design of novel drilling muds. To ensure oil wells are safe and economically viable, it is vital to maintain their integrity. Engineers have spent decades optimizing drilling muds, which are pumped into new wells to reduce friction and keep the drill bit clean. Once in the well, the liquid element of the mud seeps into surrounding rock leaving solid particles to create a mudcake, which lines the well walls to stabilize them. However, the behavior of drilling muds within wells is highly complex, and their efficacy depends on many factors, such as temperature, salinity and permeability, within the mud itself and in the surrounding rock. Ineffective muds can clog the well and lead to stuck pipe—an expensive and time-consuming problem for the oil industry. KAUST's Qi Liu and Carlos Santamarina have developed a sophisticated model of mudcake formation from water-based drilling muds for the oil industry. Their model provides insights into mudcake growth and suggests ways to ensure optimal formation. “The mudcake forms as a filtrate, similar to ground coffee in a French press, at the interface between the well and the rock,” says Liu. “Most existing mudcake models assume a sudden change between the slurry and cake phases, which is not representative,” explains Liu. “Instead, we used equations that capture the gradual transition between void ratio, permeability and effective stresses to create a model that properly represents the evolution from mud slurry to mudcake.” Their results show that environmental factors including thermal, chemical and mechanical stresses play a critical role in excessive mudcake growth, along with high permeability and low mud viscosity which causes severe fluid loss within the system. “We also found that the total force acting on the pipe increases with time,” says Liu. “Therefore, our primary advice to avoid stuck pipes is to minimize time spent at a standstill. Drilling companies must also optimize mud design by taking complex downhole conditions into consideration.” The team is also working on engineered muds that allow users to monitor them directly. These include a new magnetic-sensitive mud, nanoparticle-based muds with unique properties, and stimuli-reactive muds that change properties upon request.